Loading...

Loading...

Loading...

Loading...

Color of films: all kinds of colors

Gloss: Website data update...

Packing specification: 20±1kg/barrel

Mixing ratio: 10:1

Actual spreading rate: Metallic Paint 4-6㎡/kg

Film thickness of coating: 20-30μm/track

Dry film of varnish: 25-30μm/track

Product Introduction:

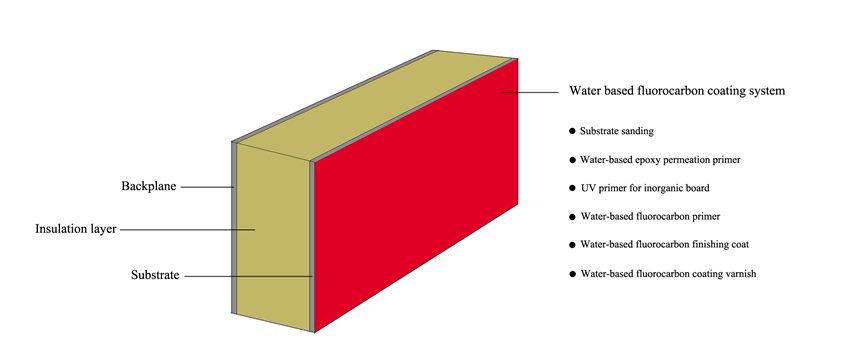

The fluorocarbon coating dedicated for thermal-insulation and decorative integrated plate adopts high-quality water-based fluororesin as the base material, mixed with inorganic ceramic pigment and high-performance auxiliaries. It is a kind of crosslinking consolidated two-component water-based fluorocarbon coating. It has excellent performances of super weather resistance, acid resistance, alkali resistance, salt fog resistance, corrosion resistance, anti-pollution and oil rub resistance. It is widely used in the base materials of calcium silicate board, cement board, aluminum plate and so on.

Coatingprocess:

Technical parameter:

Project

ZF-WY110 Water-based fluorocarbon primer

ZF-W110 Water-based fluorocarbon finishing coat

Appearance and Color

Light grey,white

Various color dispersions

Fineness

≤20um

≤20um

Solid content,%

≥40

≥50

Practical Coverage

4-6㎡/kg(dry film 20um)

4-6㎡/kg(dry film 30um)

Coating / curing agent

10:1

8:1

Surface dry,(25℃)

≤1h

≤1h

Hard dry,(25℃)

≤3d

≤3d

Spray viscosity(-4 cups)

50±10s

50±10 s

Hardness

≥1H

≥1H

Adhesive force

≤1

≤0

Resistance to artificial aging

≥1000h

≥3000h

Impact resistance,cm

50

50

Acid resistance(50g/L H₂SO₄ liquid)

168h without abnormalities

168h without abnormalities

Alkali resistance(50g/L NaOH liquid)

168h without abnormalities

168h without abnormalities

Craft product system:

|

Serial No. |

Technological Process |

Product used |

Technological Requirements |

Specific Details |

|

1 |

Preprocessing(Polish) |

Coarse sand, fine sand, fine sand |

Flatness, roughness to meet the requirements |

With coarse sand, fine sand and fine sand polished, Post dust removal |

|

2 |

Water-based epoxy permeation |

ZF-WB110 |

Permeate in balance, and permeate 1.5-2mm |

Coverage 20-22㎡/kg,viscosity about 13s |

|

3 |

Dry in the air |

|

Surface dry |

Still standing for 3min,adopt wet-on-wet technique with the next coating |

|

4 |

UV primer for inorganic board |

ZF-UV1000 |

Film is level、dense,Glossy uniform |

Amount about 100-120g/㎡ |

|

5 |

Dry |

|

Roller coat,UV light curing |

Fine sand grinding and dust removal |

|

6 |

Water-based fluorocarbon primer |

ZF-WY110 |

Film is level, no sagging and flooding ,Glossy uniform |

viscosity 50±10s,Dry film 15-20μm |

|

7 |

Dry in the air |

|

Surface dry |

Still standing for 10-20min,adopt wet-on-wet technique with the next coating |

|

8 |

Water-based fluorocarbon finishing coat |

ZF-W110 |

Film is level, no sagging、Glossy uniform |

viscosity 50±10s,Dry film 30-40μm |

|

9 |

Dry |

|

Film is completely dry (hard dry) |

50±10℃ Bake 2±1h ,25℃Dry in air 2-3d |

|

10 |

Water-based fluorocarbon coating varnish |

ZF-W115 |

Film is level, no sagging and flooding ,Glossy uniform |

Spray 1Avenue,Dry film 15-20μm |

|

11 |

Dry |

|

Film is completely dry (hard dry) |

50±10℃ Bake 4±1h ,25℃Dry in air 2-3d |

B-808, International Trade Building or Cetra Building, No. 187, No. 308 National Road, Chengyang District, Qingdao

+86-0532-89080157 , +86-135-8921-7101

+86-0532-89080158

Email: futanqi@126.com